Slip clutches are crucial machine components. They’re used in a variety of applications to make machinery more functional while also protecting it against excessive force. They’re found in motorcycles, cars, heavy machinery, and many other settings. In each instance, they provide added protection while also ramping up speed, adding necessary tension, regulating torque, and performing other tasks. The following Essential Insights into Slip Clutch Mechanisms can help users better understand these components and make the most of them.

How Do Slip Clutches Work?

Table of Contents

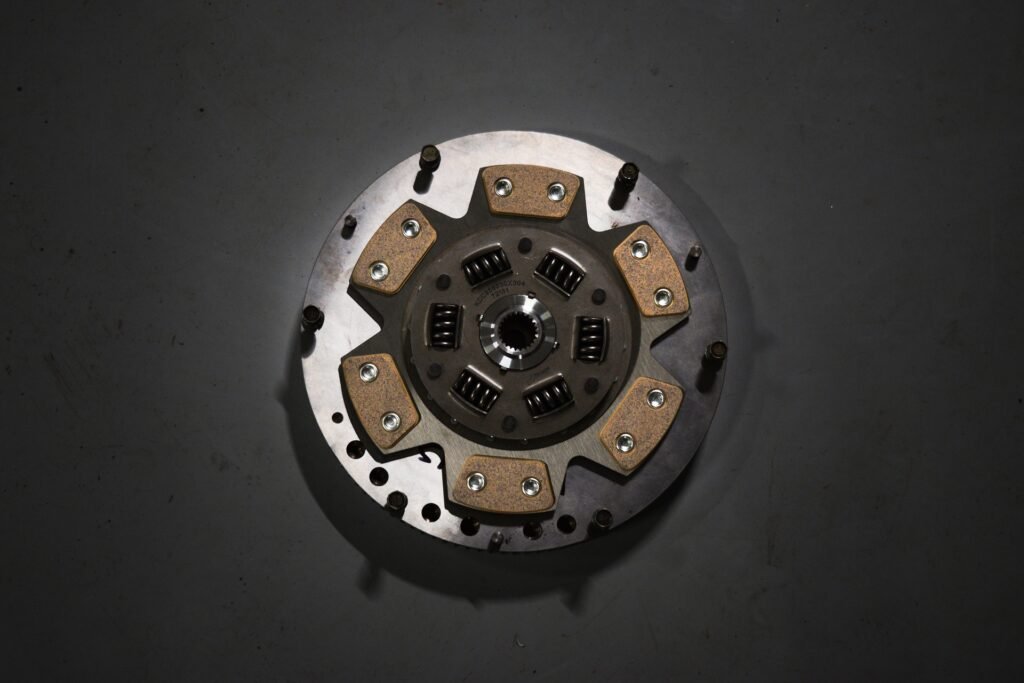

Several types of slip clutches are available for different uses. In general, though, they all work on the same basic principles. Slip clutch mechanisms connect two rotating parts. One is the driving component, like a motor, and the other is what’s being driven, such as a machine tool. Inside the slip clutch, an inner and outer component rotate relative to each other, and there’s a spring-loaded part or some type of special friction material between them.

While a machine that’s equipped with a slip clutch mechanism is running, the driving component and the one being driven work together using mechanical force. Most of the time, they work smoothly. In some cases, though, they may get jammed or, for some unexpected reason, run into excessive resistance.

Under ordinary circumstances, an issue like that could cause serious damage. With a slip clutch in place, that damage can be avoided or at least minimized. This part acts as a safeguard to reduce the amount of force applied to the previously mentioned components. That can prevent extensive damage and costly repairs. In doing so, it may reduce downtime for industrial machinery. In the case of automobiles and motorcycles, it can prevent potentially dangerous accidents as well as damage.

What Are the Benefits of Slip Clutch Mechanisms?

As mentioned, slip clutch mechanisms can prevent a great deal of damage and downtime while also potentially reducing the risk of injuries from malfunctioning machines. That, alone, makes them essential components, but it’s only one piece of the puzzle. These components can also provide a variety of other benefits.

Slip clutches can help machines run faster without placing unnecessary strain on their parts. They allow for better torque and tension control as well as greater efficiency. At the same time, with so many setups available, they can be used in a variety of applications and designed according to different user’s needs. They’re effective in numerous types of machines from printers to mining equipment.

Making Machinery Last Longer and Work Better

Slip clutch mechanisms are widely used in an array of applications. One of their main purposes is to serve as a safety feature to prevent excessive strain and overloads. That reduces damage and can make machinery last longer. They can also help users regulate power transfer and speed up their machines without sacrificing safety and longevity. These components are found in household washing machines, bulldozers, farm tractors, and beyond. In general, they make machinery last longer and work better, and they can prevent a number of costly problems along the way.