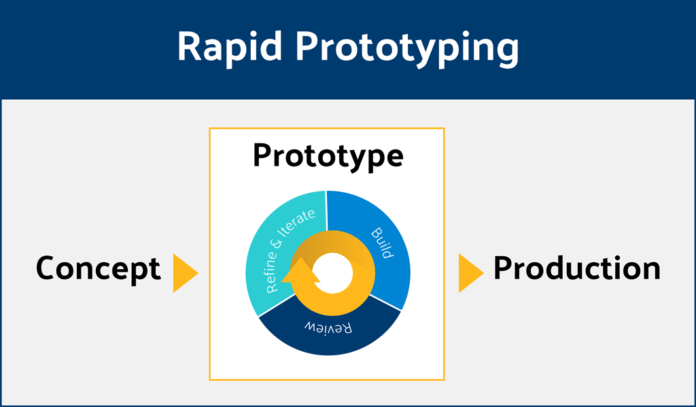

Rapid prototyping is the process of creating a physical or digital model of your product idea in order to test it with potential customers. This can be done with a variety of materials, including 3D printing and CNC machining. Rapid prototyping allows you to get feedback from customers early on in the design process, which can help you improve your product before you even begin manufacturing. In this guide, we will discuss the basics of rapid prototyping and how to get started with it yourself!

Rapid Prototyping:

Table of Contents

The benefits of rapid prototyping are many. In addition to getting feedback from customers, it can also help you verify the dimensions and functionality of your product. This can save you time and money in the long run, as you will not have to make changes to your design after it has been manufactured. Rapid prototyping is also a great way to test new ideas or material choices before committing to them.

If you are interested in learning more about rapid prototyping, there are a few resources that can help you get started. We recommend checking out our blog post on the subject, as well as our video tutorial on how to create a digital model of your product idea. These will give you a good foundation for understanding the process and what it can do for your product development.

Once you have a good understanding of the basics, you can start experimenting with different materials and methods to find what works best for you. There is no one-size-fits-all approach to rapid prototyping, so don’t be afraid to try something new! We hope this guide has been helpful in getting you started on your journey to creating the perfect product. Happy prototyping!

Rapid Prototyping:

The Guide to Molding Your Product Ideas Rapid prototyping is the process of creating a physical model of your product idea in order to test it with potential customers. The best rapid prototyping tool for this is a 3D printer.

The Guide to Molding Your Product Ideas

It works by spraying liquid resin onto the surface of a CAD model and letting it cool, solidify, and harden in what is known as “rapid cooling.” Because you don’t have to wait for your design to be completed before testing it with customers, you can develop new features or alter existing designs more quickly.

This will save you time and money over time because you won’t have to make redesigns after your product has been produced. 3D printing is another method for prototyping that can save time and money.

Rapid prototyping also allows you to test new ideas or materials before committing to them. If you want to learn more about rapid prototype technology, there are a few resources available to assist you. We recommend reading our blog article on the topic as well as our video tutorial on how it’s done.

Having a solid grasp of the fundamentals will help you to better understand how it works and what it may accomplish for your product development. Once you’ve mastered the basics, you can start experimenting with different materials and techniques to see which ones work best for you.

Conclusion

There’s no such thing as a one-size-fits-all rapid prototype solution, so don’t be scared to experiment! We hope that this tutorial has been helpful in getting you started on your product development journey. Good luck with your prototyping!